Plating jewelry, a popular term in manufacturing jewelry and becomes an ideal option for jewelers due to its optimal cost as well as gorgeous and long-lasting appearance. Follow us to understand how a piece of jewelry is plated.

Surface Preparation

The purposes of this step are to keep impurities away from the plating tanks and then increase adherence since dust and filth prevent the plated metals from sticking to the jewelry piece.)

The jewelry is extensively polished before being ready for electroplating. A tiny bump or grainy texture will make the plating appear blotchy and uneven; thus the artisans will buff the item's surface to a flawless shine. The object is electro cleaned and repeatedly washed in the following baths after polishing: distilled water, neutralizer, distilled water, micron plating dip, distilled water.

Base coat

The jewelry might be given a palladium or nickel base coat before the gold/rhodium or other metals is added for base metals that are challenging to plate on their own. This extra layer of protection helps ensure that the outer plating adheres properly and has a longer lifespan. In addition, this process adds strength and durability to the jewelry piece, ensuring it stands.

Electroplating

In this stage, jewelry pieces are dipped into the plating solution to draw out the ions of the metal that will eventually be visible on the surface. Temperatures and voltages must be adjusted for various metals.

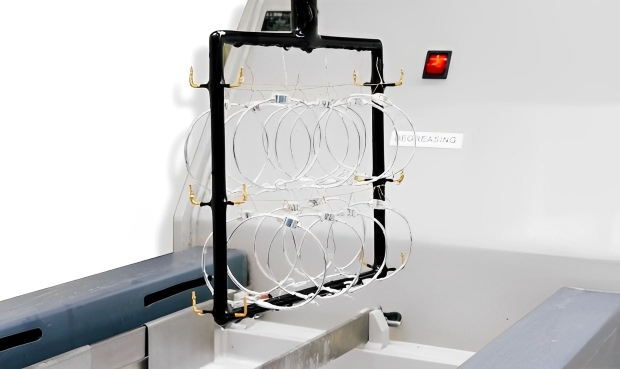

The objects that will be plated are suspended from a cathode bar, which is a pole that conducts a negative electrical charge. Also negatively charged are the jewelry pieces attached to the cathode bar. When the jewelry items are submerged in the tank an electrical charge is applied and the negatively charged jewelry attracts the positively charged ions present in the solution. The solution bath is filled with the metal ions that are positively charged. Jewelry made of metal becomes plated when the cathode bar is placed into the bath. Depending on how thick the plating is supposed to be, the jewelry remains immersed for a particular period of time.

At the end of the day

With all of this in mind, it is important to choose an experienced professional for your jewelry plating needs. Shinera Vietnam has been providing high-quality plating jewelry for years. We offer different plating colors including yellow/rose gold and rhodium with thickness as our customers’ requirement. Our specialized equipment and expertise ensure that each piece of jewelry receives a flawless finish with lasting results. Contact us today for more details.